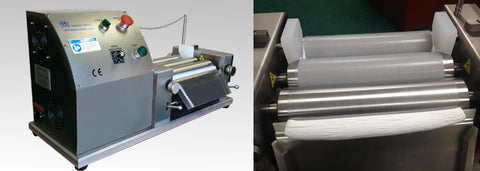

T65B (2.5x10) Three Roll Mill - Super-Charged Pilot Production Model

Experience the Latest From the Award Winning Manufacturer -

Torrey Hills T65B (2.5x10) Three Roll Mill.

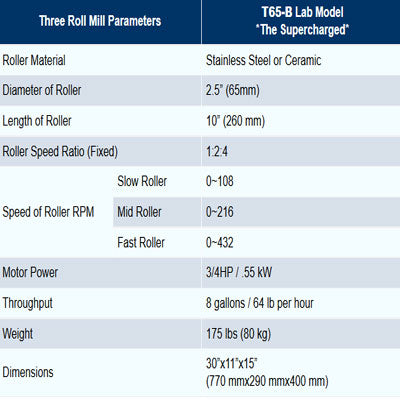

Compared with the tremendously popular T65 (2.5"x5") lab model, this machine is equally equipped with state-of-the-art control, streamlined design and modern all stainless steel structure. This three roll mill is ideal for laboratories and pilot production for mixing electronic thick film inks, high performance ceramics, cosmetics, paints, printing inks, adhesives, epoxy, sealants, pharmaceuticals and many other viscous materials.T65B model offers fast roller speeds and high throughput up to 8 gallons or 64 pounds per hour. The fast roller runs at 432 RPM. Variable frequency drive allows stepless speed control and slow speed runs. Roller spacing and adjustment is set manually with quick engagement mechanism by the use of four small hand wheels. Safety trip limit switch (in the form of a pull cord), emergency stop button, slow-speed washup mode capability and nip guard make this three roll mill very safe to operate. Other advantages include self-lubricating gears and Teflon end plates.

Premium Features

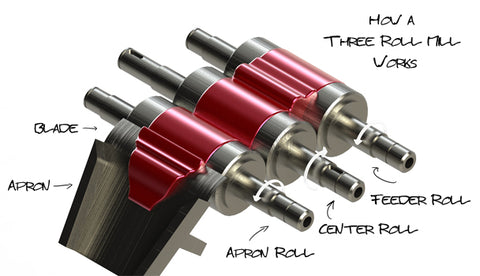

- Rollers

- Three 10”- long rollers ensure high output.

- Stainless steel rollers are made from precision ground 420J2 stainless steel to prevent rust or erosion. The hardness is rated at HR50-60 for reliable long-life usage.

- Ceramic rollers are made from cold iso-static pressed and fired 99.5% alumina. Three roll mills with ceramic rollers are recommended when metallic contamination is a concern for the milling process. Our ceramic rollers have been widely used in such applications as thick film paste, Dye Sensitized Solar Cell research, fuel cell research, etc.

- Rollers are ground to 5μm concentricity and 0.5μm surface finish for precise applications.

- Rollers are cored for either cooling for heating to meet the needs of different mixing conditions. Manifold, valve, and collection tank are standard.

- Motor

- Powerful motor is able to handle high-viscosity materials at high speed.

- Variable speed control allows adjustable/slower speed runs.

- Gap Adjustment

- Roller spacing and adjustment are set manually with quick engagement mechanism by the use of four small hand wheels, The mechanism is a combination of flexibility and stability.

- Gap spacing remains consistent and rollers stay perfectly parallel to each other throughout operation.

- Accessories

- Easily adjustable Teflon end plates prevent materials from splashing out from gaps and sides.

- Teflon scrapper blade is durable, individually replaceable as well.

- Stainless steel receiving apron provides a nonporous, smooth surface promising minimum leftovers on it.

- Unit includes a free standing base allowing easy mobility.

- Safety

- Easily accessible stop and start buttons.

- Emergency pull cord on top of the machine as an extra safety feature.

Please contact us for more information. We are always happy to help and will always respond.

Tel: +44 (0) 207 118 3123 or Click here to send us an email.